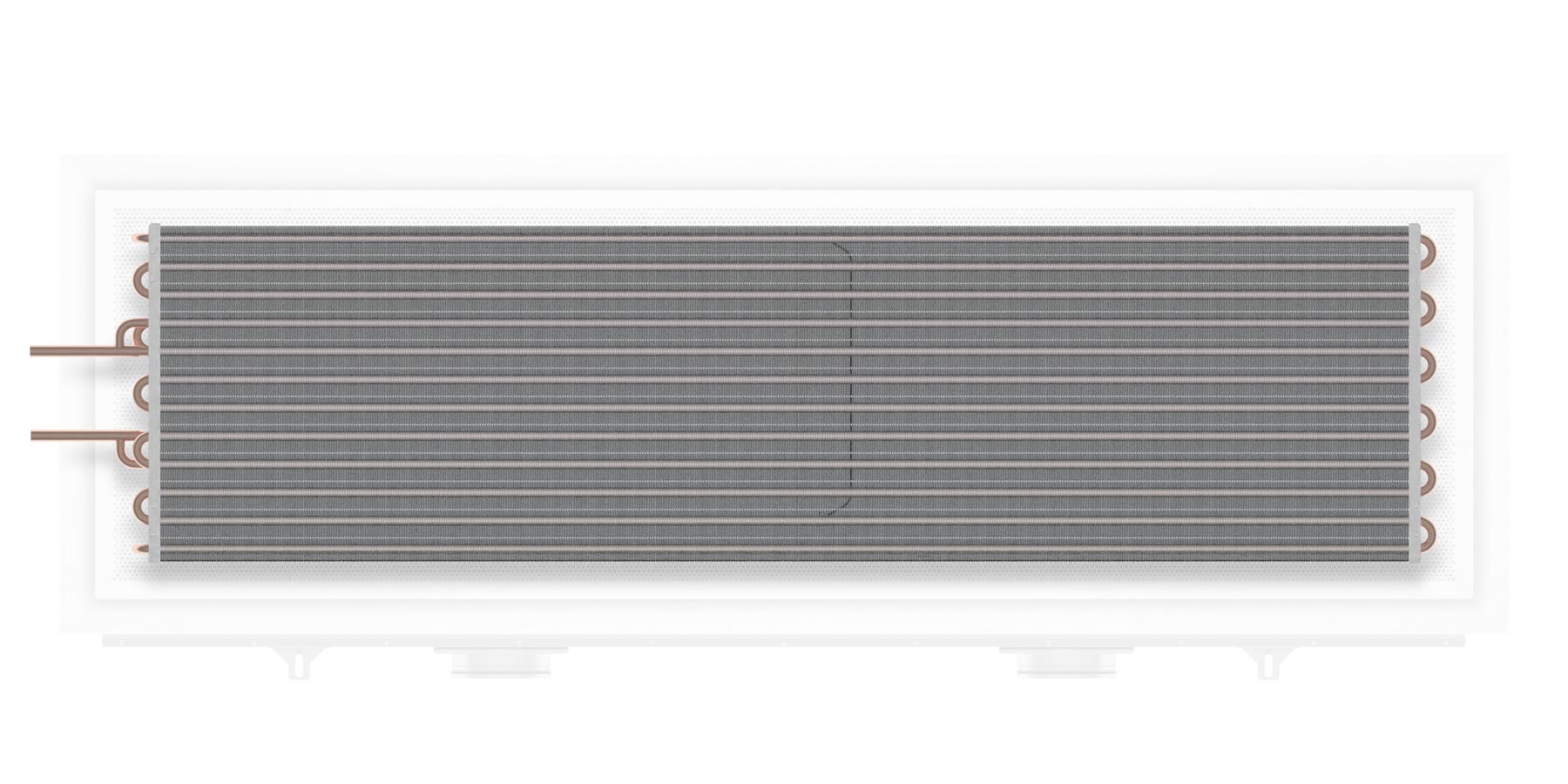

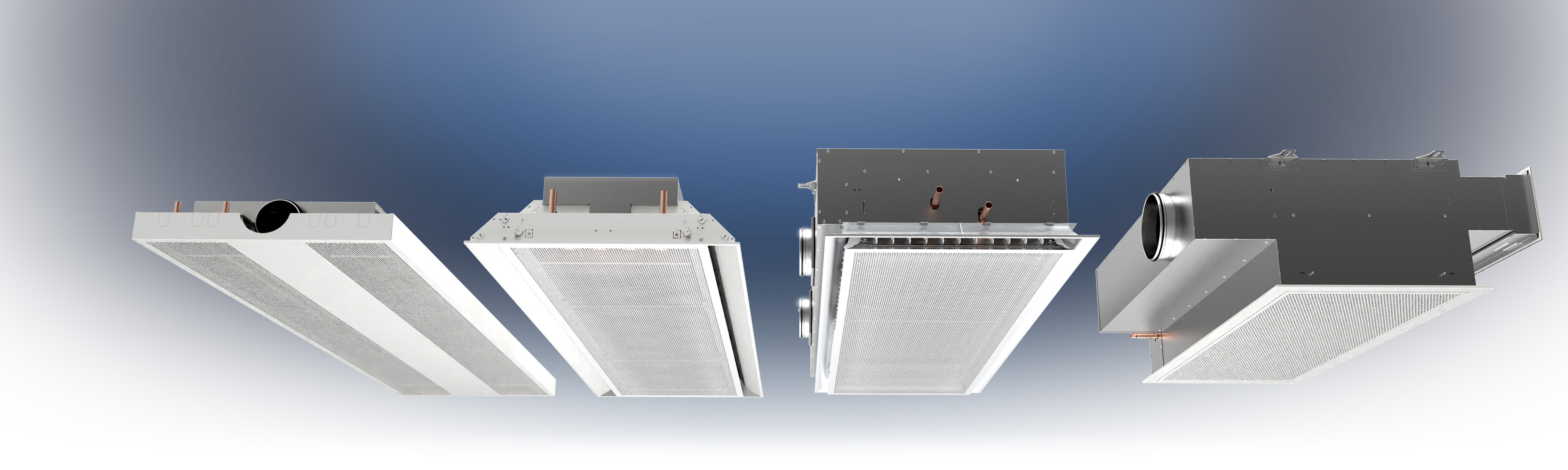

Chilled beams – efficient comfort

Better for people. Better for the environment.

Scandinavian building design is defined by functionality, simplicity, and long-term sustainability. Chilled beams align naturally with these principles – a quiet, reliable solution with no moving parts, combining the high thermal capacity of water with the induction effect of air. The result is stable indoor comfort, low energy use, and minimal maintenance. The following sections outline how chilled beams work, their key advantages, and where they perform best – giving building owners, designers, operators, and users a clear foundation for sound, practical decisions.

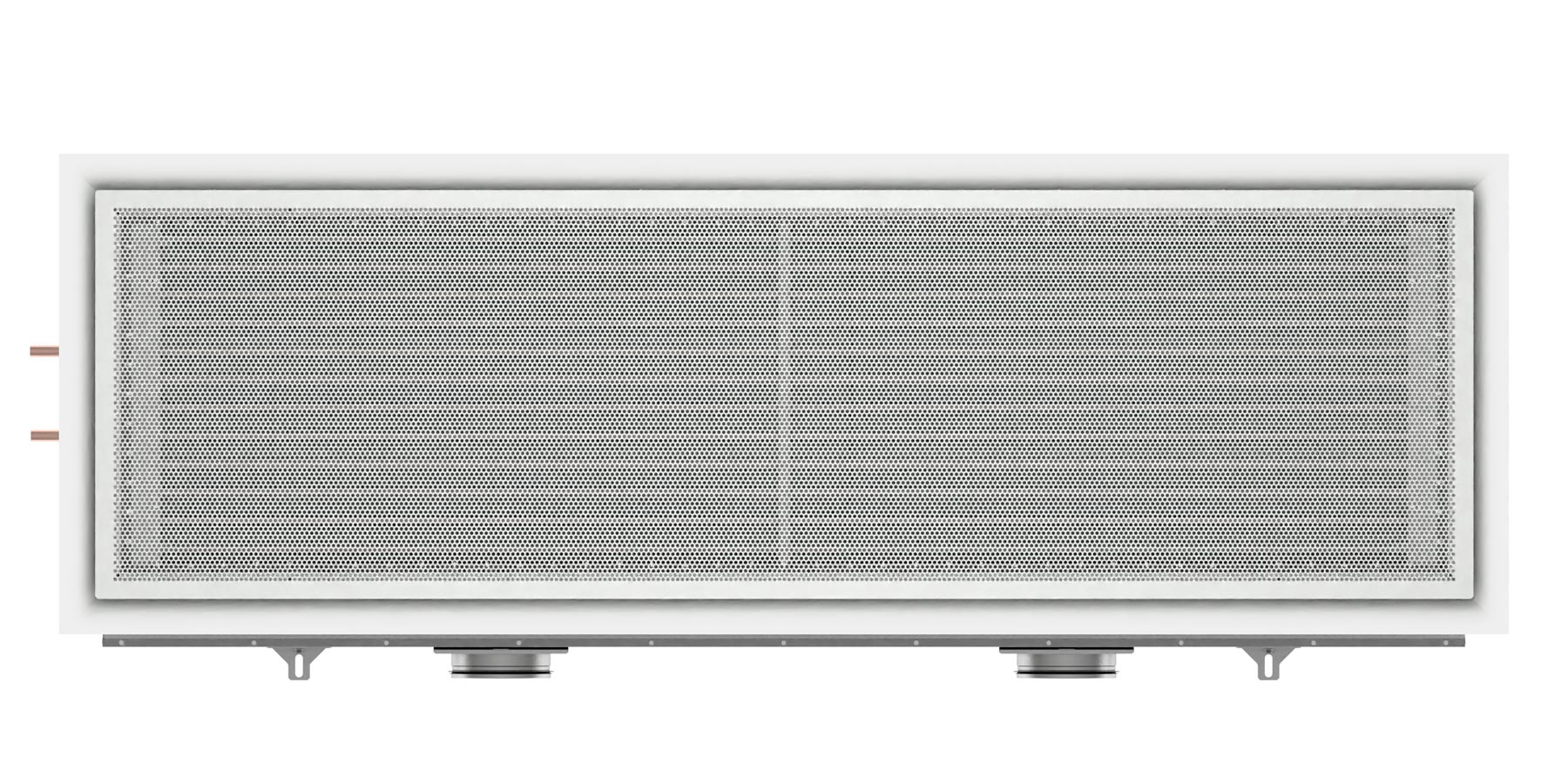

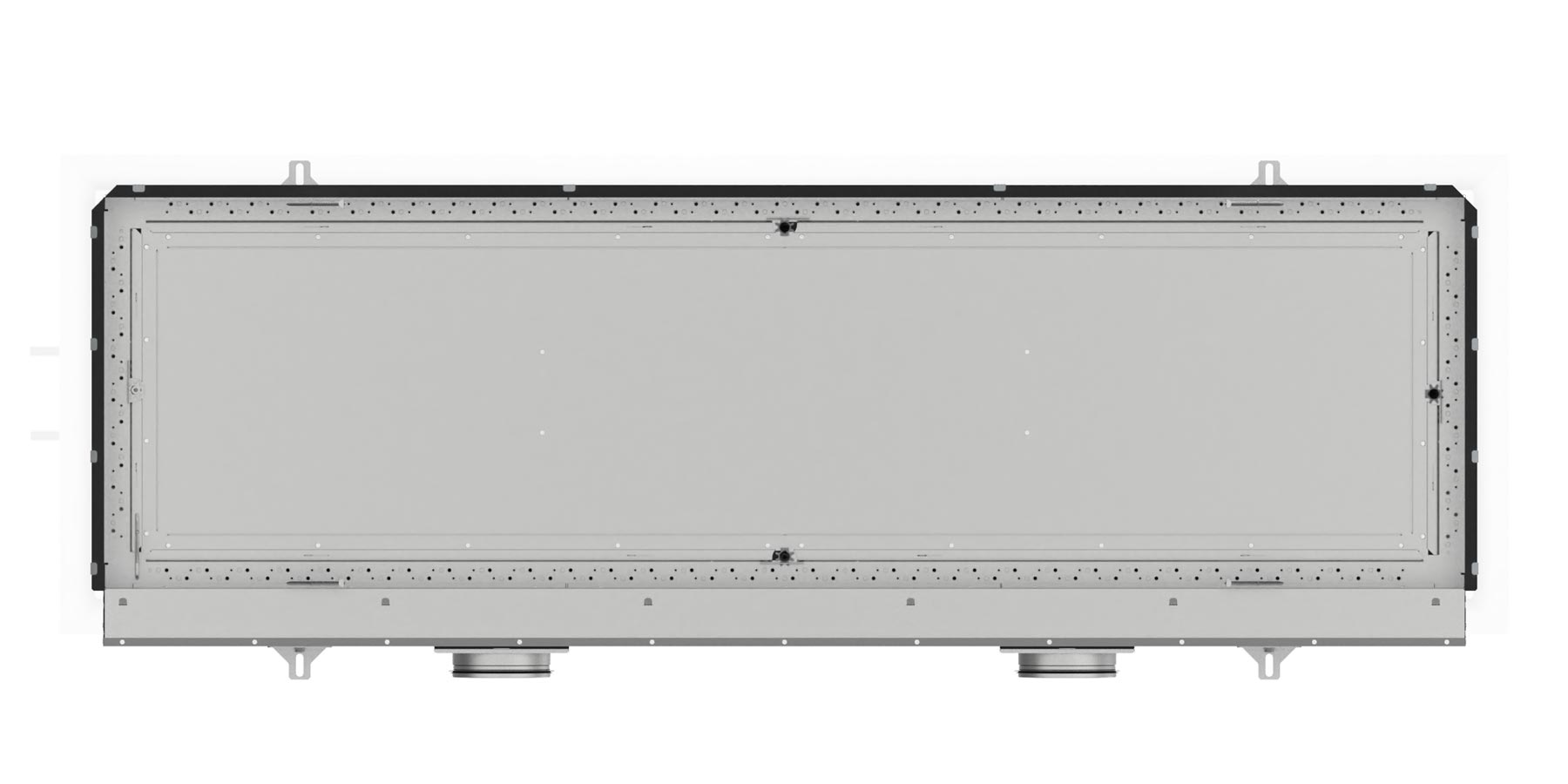

![Chilled beam types 2/2 [cc]](https://airvent.hu/uploads/images/reportair/2025/cb/active_passive/active_06.gif)