For Airvent to be a successful demand-controlled ventilation systems provider, we have to design and develop our own control and software solutions.

Airvent aims to develop and provide carefully designed, user-friendly, integrated ventilation system solutions, which are able to automatically provide healthy, energy-efficient and pleasant indoor climate. We are talking to László Pintér, technical director at Airvent.

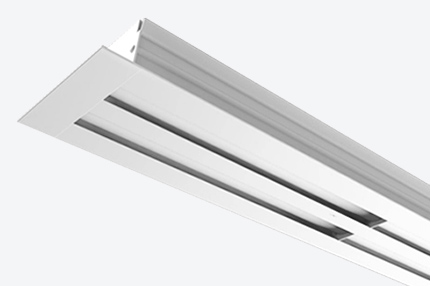

Nowadays, most new buildings are designed to reach the highest possible energy rating, which must guarantee both economical operation and adequate comfort for decades. Thanks to smart engineering solutions, Airvent's products are energy efficient and can be further enhanced through an automatic, intelligent, and demand-based operation system. László Pintér has a tremendous importance in everything that happens at Airvent. He began his career at Airvent as an electrical engineering student in the Budapest based office. He quickly progressed and took part in the development and sales process of air handling units, as well as in the communication of technical procedure to customers. Today, he leads a group of around 30 people and is responsible for the future developments of Airvent’s product roadmap.

The road from student to technical director.

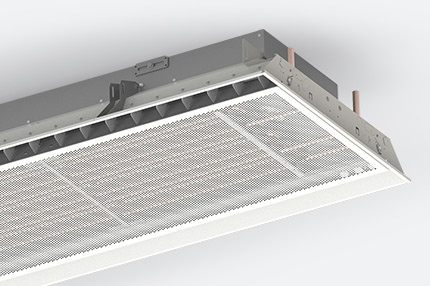

I first learned about Airvent when Mr Pataki – founder and then CEO of the company – invited me to Kecskemét to show me their first automation development project they had been working on. The aim of the project was to create an automatic control system for their chilled beams, as at that time there were no manufacturers, whose existing solutions could meet Airvent’s vision and requirements for the functional demands. When I joined, our two main targets were to create control solutions for chilled beams and for our Plex air handling unit series. These objectives were met in 2009, when we could offer integrated and complete automatic solution for both aforementioned product groups. Since my arrival, our range of activities and staff have grown to be able to meet new objectives that is intended to keep Airvent on the path of growth, in addition to offering our partners well-built, smart ventilation solutions.