FAQ

Building management system?

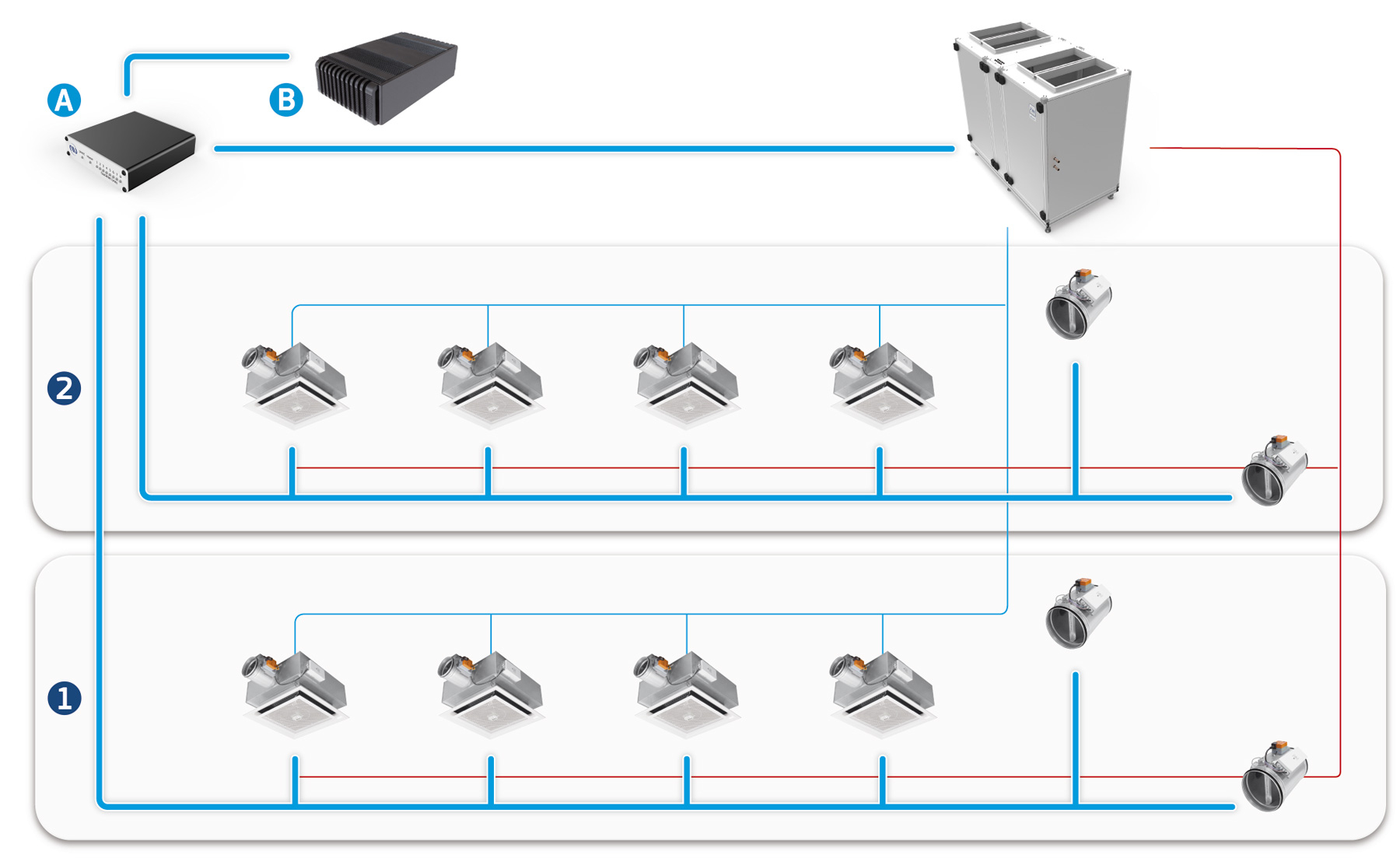

We would rather call it a ventilation and climate management central. Imagine an air handling unit controller - but larger - which includes the controlling of the complete ventilation system.

I do not need management systems. The room regulators can operate standalone.

This is of course a legitimate perspective. We focused on the maximum efficiency, while maintaining the ease of operation and the best indoor air quality possible. Let us not forget, the highest energy savings can only be achieved through clever, precise and demand controlled operations. The air handling unit and local room controllers are not able to do these type of energy efficient operations by themselves.

Management system can be too complicated, often causing unnecessary problems.

The SUM management system is built up by modules. The operation of the pre-programmed and pre-configured modules are transparent and easy to understand. The clean design of the web-based management interface was developed specifically with the user in mind.

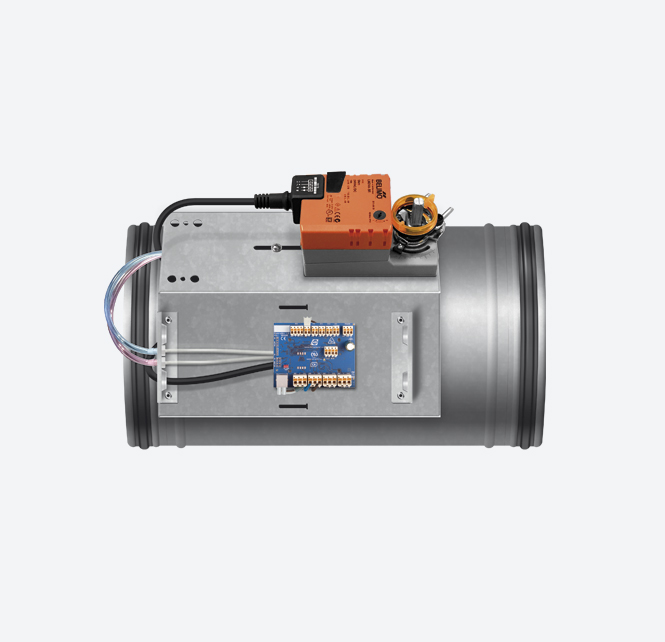

Why do I need a zone pressure controlled system?

In our view the pressure control is the key for the highest efficiency in operation. A demand controlled system needs to have constant pressure control. The ventilation intensity depends on the outdoor conditions, but provides ground ventilation at all time. The maximum capacity of the ventilation system is actually only used during the warmest days of the year.

Can SUM be connected to a traditional Building Management System?

Yes, Modbus RTU and Modbus TCP/IP protocols are available, if requested.

How much does a data point cost?

The SUM management system is not measured by data points. The cost is determined primarily by the dimension of the system and by the number and type of selected SUM modules. Our system is very understandable, which makes it easy to set-up the budget plan for the controlling.

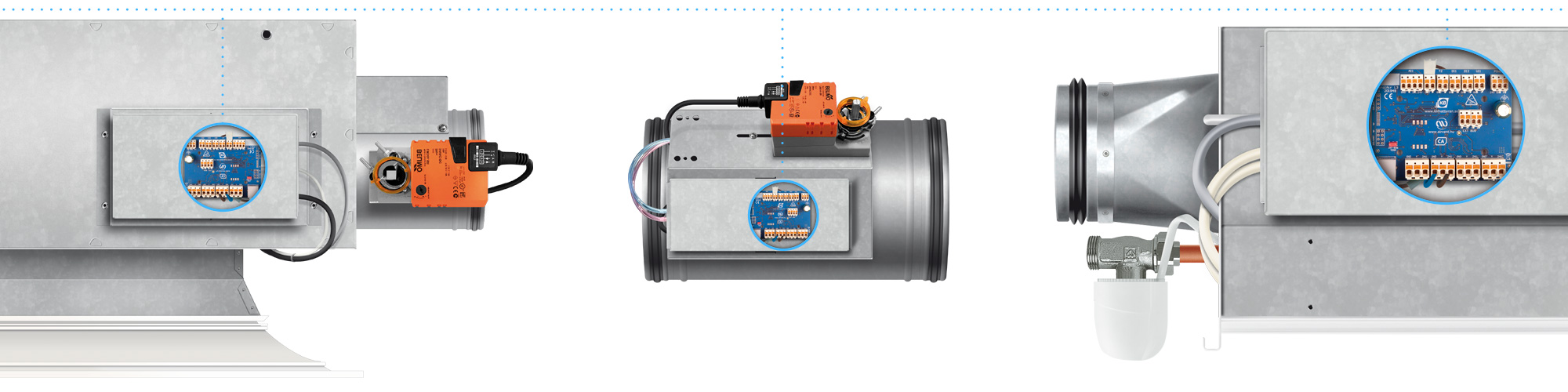

Can the cooling and heating systems also be controlled?

Yes, SUM includes a module, which is able to control the circulation pumps of the cooling and heating systems.

I have a multi-story building. Which user interface should I order?

SUM provides a comprehensive layout view for each floor in the building, as well as a room list. The rooms and layouts can be displayed according to the numbers of floors.

What is required for the system to operate?

230VAC socket in the server room. All elements of SUM is pre-programmed at Airvent. After the on-site installation the system operates immediately.

What happens if a fault occurs?

SUM as a system optimiser is not operation critical of the system. Without the operations of SUM, the products and local regulators will continue to run according to the last valid settings.

Can the users ”shut” down the system?

Different user levels ensure safe operation.